Press Release

O&L LEISURE UNVEILS NEW BRAND IDENTITY REFLECTING PREMIUM MARKET VISION AND COMMITMENT TO EXCELLENCE

O&L Leisure, a subsidiary of the Ohlthaver & List (O&L) Group, is proud to announce its rebranding as part of a strategic move to position itself as a premium provider of authentic, luxury travel experiences. This transformation aligns with O&L Leisure’s evolving vision and growth strategy, reflecting its commitment to offering world-class service while maintaining deep connections to its Namibian heritage.

The new brand, featuring a sleek and refined logo, captures the spirit of O&L Leisure’s dedication to authenticity, care, and passion. Designed to appeal to a premium, international market, the rebrand underscores O&L Leisure’s ambition to elevate its offerings while remaining true to its Namibian roots.

Sven Thieme – Executive Chairman, O&L Group and Managing Director, O&L Leisure.

Sven Thieme, Managing Director of O&L Leisure and Executive Chairman of the O&L Group, elaborated on the rationale behind the rebranding: “As we expand our reach and transition into the premium and super-premium markets, we recognise the need to refine our brand to reflect our new audience. This rebrand positions us to speak directly to our new audience and convey the luxury, authenticity, and world-class standards we uphold across all our properties. Our guests will know that no matter which O&L Leisure property they visit, they will experience the same exceptional standard.”

The rebranding is also a pivotal part of O&L Leisure’s broader strategy as it prepares to grow its portfolio. The new identity reflects a unified promise across all O&L Leisure properties, ensuring a consistent, premium guest experience while allowing each location to retain its unique charm.

Thieme added: “With our expansion plans, we are committed to maintaining one consistent standard across all properties. While each destination – whether it’s Chobe Water Villas or Mokuti Etosha – has its unique appeal, the golden thread throughout will now be more visible than ever. Our new brand is a promise to our guests that they will enjoy world-class service, comfort, and authenticity, wherever they choose to stay.”

The new logo reflects this refined approach, combining modern sophistication with a deep respect for the brand’s Namibian heritage. Retaining the iconic “1919” symbol, the logo emphasises O&L’s legacy while embracing a minimalist and elegant design. The new tagline, “Namibia Through Our Eyes,” encapsulates O&L Leisure’s mission to provide genuine, unfiltered experiences that connect guests to the heart of Namibia.

Thieme explained: “We are proud to showcase Namibia’s true essence through this rebrand. The new tagline is not just a slogan; it represents our authentic, caring, and passionate approach to hospitality. Every interaction with our guests, every detail of their experience, is designed to reflect the beauty and soul of Namibia.”

As part of its enhanced visual identity, O&L Leisure has introduced new secondary colours such as Dune Beige and Golden Metallic, reflecting Namibia’s stunning landscapes and the unforgettable moments shared in its properties. The golden thread in the branding represents the connection between all O&L Leisure destinations, offering a sense of place and a promise of luxury.

(from left to right): Shepherd Chinhoi – Operations General Manager; Franziska Rueeck – Chief Experience Officer, O&L Group and Quality & Experience General Manager, O&L Leisure; Sven Thieme – Executive Chairman, O&L Group and Managing Director, O&L Leisure; Maryke van Lill – Marketing Manager, O&L Leisure; Victory Shimwandi – Sales Manager, O&L Leisure and Sonja Bartsch – Financial Director, O&L Leisure.

The rebranding aligns with O&L’s Vision for 2029, which includes global recognition for service excellence and a focus on being one of the top 10 Great Places to Work (GPTW). By enhancing its brand and service standards, O&L Leisure aims to set new benchmarks for luxury travel, both in Namibia and internationally.

Sven Thieme concluded: “Our new brand is a crucial part of O&L’s Vision for 2029. We are committed to providing exceptional guest experiences, while creating a work environment that empowers our team to grow and thrive. By elevating our brand and service, we are not only showcasing the best of Namibia to the world, but we are also contributing to our long-term financial goals and ensuring each property operates at the highest standards of efficiency and excellence.”

This bold rebrand reinforces O&L Leisure’s dedication to offering handpicked, unique locations that tell Namibia’s story and create memorable, world-class experiences for all guests.

About O&L Leisure:

O&L Leisure is a subsidiary of the Ohlthaver & List (O&L) Group, offering premium, authentic hospitality experiences in Namibia. Its portfolio includes Strand Hotel Swakopmund, Midgard, Mokuti Etosha, and Chobe Water Villas, with expansion plans underway. O&L Leisure is driven by its mission to provide luxury experiences rooted in Namibia’s natural beauty and culture, ensuring a consistent world-class standard across all properties.

Media Contact

Organization: The Ohlthaver & List (O&L) Group

Contact Person: Roux-ché Locke

Website: https://www.ol.na

Email: roux-che.locke@ol.na

Contact Number: +264612075207

Address: Alexander Forbes House, 7th Floor,

Address 2: South Block, 22-33 Fidel Castro Street, Windhoek, Namibia

City: Windhoek

State: Khomas

Country: Namibia

Release Id: 26092417515

The post O&L LEISURE UNVEILS NEW BRAND IDENTITY REFLECTING PREMIUM MARKET VISION AND COMMITMENT TO EXCELLENCE appeared on King Newswire. It is provided by a third-party content provider. King Newswire makes no warranties or representations in connection with it.

About Author

Disclaimer: The views, suggestions, and opinions expressed here are the sole responsibility of the experts. No Digi Observer journalist was involved in the writing and production of this article.

Press Release

Cloom Tech Manufactures Robotic Custom Wire Harness Assemblies

China, 12th Mar 2025, – Cloom Tech, a provider of custom wire harnesses and cable assemblies, has expanded its specialization in manufacturing custom wire harness assemblies for robotic applications. This development enhances the company’s ability to deliver wiring solutions tailored to the increasing demands of automation and robotics across industries such as manufacturing, healthcare, and aerospace.

With a focus on precision and durability, Cloom Tech now offers robotic wire harness assemblies designed to withstand continuous movement, high-speed operations, and harsh industrial environments. By integrating high-quality materials and quality control measures, the company ensures that each assembly meets industry standards and operational requirements.

“The expansion into robotic custom wire harness manufacturing aligns with the demand for reliable and flexible wiring solutions in automation,” said Ivy Zhao, spokesperson for Cloom Tech. “By refining expertise, the goal is to support industries that rely on robotics to enhance efficiency and operational precision.”

Robotic systems require specialized wiring solutions that can endure repetitive motion and mechanical stress while maintaining signal integrity. As automation advances, the need for custom wire harnesses capable of handling complex electrical connections has grown. Cloom Tech’s engineering and manufacturing processes ensure that clients receive solutions optimized for durability, flexibility, and performance reliability.

Each robotic wire harness assembly undergoes testing to verify electrical integrity and mechanical resilience. Cloom Tech employs manufacturing techniques to produce assemblies that meet industry regulations and client-specific design requirements. These solutions support robotic functionality in sectors such as industrial automation, medical robotics, and autonomous systems.

Beyond manufacturing, Cloom Tech provides design support for robotic wire harness solutions, assisting clients in optimizing specifications for their applications. The company’s engineering team works closely with clients to develop customized wiring configurations, ensuring integration with robotic systems. From prototype development to full-scale production, Cloom Tech maintains a structured process focused on quality and efficiency.

Cloom Tech continues to explore advancements in wire harness technology, including innovations in lightweight materials, shielding techniques, and integration with automation systems. As the robotics industry evolves, the company remains committed to delivering wiring solutions that align with technological developments.

“Cloom Tech is focused on advancing wiring solutions for automation,” added Zhao. “Through research and development, the objective is to provide connectivity solutions that contribute to robotics across industries.”

Cloom Tech’s expansion into robotic custom wire harness assembly manufacturing strengthens its role as a provider of wiring solutions for automation systems. By maintaining a commitment to quality, precision, and industry collaboration, the company continues to support technological advancements in robotic connectivity.

For more information about Cloom Tech’s robotic custom wire harness assembly manufacturer services and other wiring solutions, contact Cloom Tech at +86-311-86935537-6043 or sales@cloomtech.com. The office is located at 5th Floor, Building 5, Qiushi Electronic Science Park, Optics Valley Science Park, No. 99, Yuyuan Road, Luquan Economic Development Zone, Shijiazhuang, Hebei, China.

Media Contact

Organization: Cloom Tech

Contact

Person: Ivy Zhao

Website:

https://cloomtech.com/

Email:

sales@cloomtech.com

Contact Number: 8631186935537

Address:5th Floor, Building 5, Qiushi Electronic Science Park, Optics Valley Science Park, No. 99, Yuyuan Road

Address 2: Luquan Economic Development Zone, Shijiazhuang, Hebei, China

Country:China

The post Cloom Tech Manufactures Robotic Custom Wire Harness Assemblies appeared first on

Brand News 24.

It is provided by a third-party content

provider. Brand News 24 makes no

warranties or representations in connection with it.

About Author

Disclaimer: The views, suggestions, and opinions expressed here are the sole responsibility of the experts. No Digi Observer journalist was involved in the writing and production of this article.

Press Release

Promax Specializes in High-Quality 2-Pin Magnetic Connectors

China, 12th Mar 2025, – Promax, a manufacturer of precision-engineered pogo pins and spring-loaded connectors, has introduced high-quality 2-pin magnetic connectors designed for reliable performance across multiple industries. The latest offering meets the demand for durable and efficient connectors in sectors such as consumer electronics, aerospace, and medical technology.

With more than 15 years of experience in connector manufacturing, Promax continues to develop magnetic connectivity solutions that ensure stable electrical performance and user-friendly designs. The 2-pin magnetic connectors are designed for secure connections, reducing wear and tear compared to traditional connectors. These products are suited for applications requiring seamless connectivity and ease of use.

Gavin, Manager at Promax, stated, “The introduction of the 2-pin magnetic connectors aligns with the increasing need for compact, reliable, and efficient connectivity solutions. The focus is on delivering precision-engineered products that enhance functionality and durability while addressing operational challenges. With expertise in high-quality manufacturing, these connectors meet industry standards and provide consistent performance in demanding environments.”

The 2-pin magnetic connectors incorporate a self-aligning mechanism that simplifies connections and minimizes the risk of damage due to misalignment. The design also enhances safety by preventing accidental disconnections, making them suitable for medical devices, portable electronics, and industrial equipment.

Promax’s production facilities comply with internationally recognized quality standards, ensuring that each connector meets rigorous testing requirements for electrical conductivity, durability, and environmental resistance. The use of advanced materials and engineering techniques contributes to product efficiency and longevity.

As industries evolve, the need for high-performance connectors that support miniaturization and advanced functionality continues to grow. The increasing adoption of wearable devices, smart home technology, and portable medical equipment highlights the demand for dependable connectivity solutions. Promax remains focused on addressing these technological shifts with innovative products designed for market needs.

Promax is also expanding its magnetic connector line to accommodate various power and data transmission requirements, ensuring compatibility with a broader range of applications. Gavin added, “Innovation in connectivity solutions remains a priority. Continued investment in research and design supports the development of enhanced product offerings that align with emerging industry trends. The objective is to remain a trusted partner for businesses requiring reliable and customizable connectors for advanced applications.”

Promax’s 2-pin magnetic connectors are available for commercial and industrial applications. The company collaborates with partners and clients worldwide to provide tailored solutions that meet specific design and operational needs.

For further information about the 2-pin magnetic connector, please contact Promax. The company can be reached by phone at +86 189 2659 5104 or via email at tonyhoo@promaxpogopin.com.

Media Contact

Organization: Promax

Contact

Person: Gavin

Website:

http://promaxpogopin.com/

Email:

tonyhoo@promaxpogopin.com

Contact Number: 8618926595104

Country:China

The post Promax Specializes in High-Quality 2-Pin Magnetic Connectors appeared first on

Brand News 24.

It is provided by a third-party content

provider. Brand News 24 makes no

warranties or representations in connection with it.

About Author

Disclaimer: The views, suggestions, and opinions expressed here are the sole responsibility of the experts. No Digi Observer journalist was involved in the writing and production of this article.

Press Release

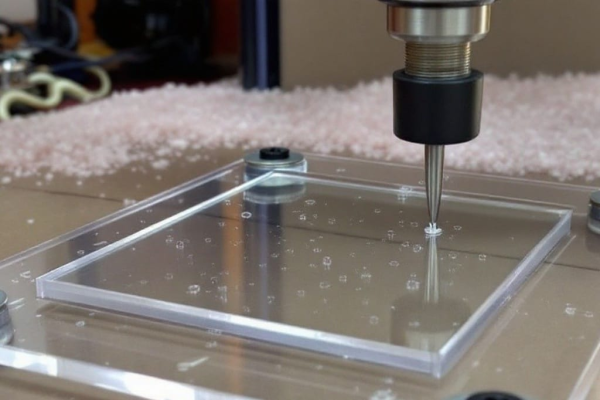

Yijin Hardware Specializes in Acrylic CNC Machining for High-Precision Manufacturing

United States, 13th Mar 2025, – Yijin Hardware, a provider of precision manufacturing solutions, has expanded its expertise in acrylic CNC machining to address the increasing demand for high-precision components. The company’s development of advanced machining techniques and quality control processes supports industries such as aerospace, medical, and electronics in producing accurate acrylic components.

Acrylic CNC machining involves specialized processes to achieve precision, clarity, and durability. Yijin Hardware has refined its machining techniques to produce high-quality components with superior edge quality and tight tolerances. Multi-axis CNC milling and cutting technology are employed to ensure that each acrylic part meets industry specifications while maintaining optical clarity and smooth surface finishes.

“Acrylic CNC machining requires precise control to produce components that meet industry standards for clarity and durability,” said Gavin Yi, CEO of Yijin Hardware. “Through continuous advancements in machining technology and quality assurance, the company remains focused on delivering reliable acrylic parts for a range of applications.”

Yijin Hardware’s acrylic machining capabilities include prototyping, small-batch production, and large-scale manufacturing. Additional post-machining processes such as polishing, engraving, and bonding are integrated to align components with specific application requirements. The company follows stringent quality inspection protocols, including dimensional verification and optical clarity assessments, to ensure compliance with industry standards.

The increasing use of acrylic components in various industries highlights the need for reliable CNC machining solutions. Yijin Hardware continues to refine its acrylic machining processes to support technological advancements and evolving product designs.

“Manufacturing processes must continuously adapt to meet changing industry demands,” added Yi. “By enhancing machining capabilities and optimizing production techniques, Yijin Hardware remains committed to advancing acrylic CNC machining for high-tech applications.”

Yijin Hardware’s continued investment in acrylic CNC machining reinforces its role in precision manufacturing. The company’s focus on process improvements and quality assurance supports the evolving needs of multiple industries.

For inquiries about acrylic CNC machining and industry advancements, please contact Yijin Hardware by phone at +1 626 263 5841 or via email at yijing@yijinsolution.com. The company’s headquarters is located at 760 NW 10th Ave, Homestead, FL 33030.

Media Contact

Organization: Yijin Hardware

Contact

Person: Gavin Yi

Website:

http://yijinsolution.com/

Email:

yijing@yijinsolution.com

Contact Number: 16262635841

Address:760 NW 10th Ave

Address 2: Homestead, FL 33030

Country:United States

The post Yijin Hardware Specializes in Acrylic CNC Machining for High-Precision Manufacturing appeared first on

Brand News 24.

It is provided by a third-party content

provider. Brand News 24 makes no

warranties or representations in connection with it.

About Author

Disclaimer: The views, suggestions, and opinions expressed here are the sole responsibility of the experts. No Digi Observer journalist was involved in the writing and production of this article.

-

Press Release6 days ago

New York’s Unleashed Spa Shares Expertise in New Article on How Grooming Affects Your Pet’s Mood

-

Press Release3 days ago

Elegant Fusion – The Cultural Symphony of Chinoiserie at ChuCui Palace Jewelry

-

Press Release7 days ago

Junk Removal Made Easy For You

-

Press Release6 days ago

Oasis Irrigation & Hardscapes Expands Sustainable Landscaping Solutions in Baldwin County

-

Press Release5 days ago

5G-A Empowering, AI Transforming, Digital Living: UniCom Showcases Digital Innovations at MWC 2025

-

Press Release7 days ago

Hawaiian Botanical Breakthrough: Mamaki Memory (TM) Launches First-Ever Brain Support Supplement

-

Press Release6 days ago

Downgrading Sage 50 Quantum a strategic decision for businesses looking to cut costs or simplify accounting operations

-

Press Release6 days ago

Transitioning from Sage 50 US to QuickBooks: A Guide